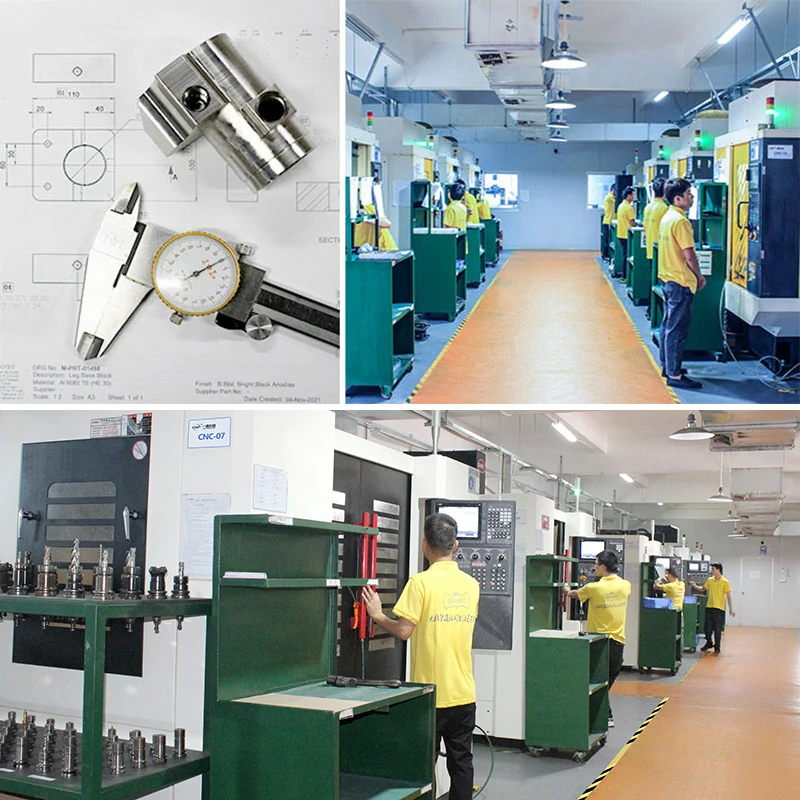

——We're professional in NC & CNC machining service and molding service for OEM and ODM parts——

Types include turning, milling, grinding, stamping, bending, welding, die casting, drilling, tapping and plastic injection. The over 6000 square meters production area is utilized with high output efficiency to produce well qualified components for different kinds of industries like medical, automotive, communication electrical and electronic.

YMP is located in Shenzhen Bao'an Shajing Street, Guangdong-Hong Kong-Macao Greater Bay Area, and next to Bao'an International Airport, Fuyong Wharf and Shenzhen International Convention and Exhibition Center, which is the world's largest international convention and exhibition center. The transportation and logistics are very convenient.

It specializes in the processing and production of precision hardware and plastic parts for photography, video equipment, auto modification accessories, audio equipment, robot and other industries.With anodizing, etching, leser cutting, paint baking, painting and other surface treatment with product assembly and rest one-stop service capabilities, It is a collection of design, processing, sales as one of shenzhen/national high-tech enterprises.

Cooperates of customers in dozens of countries domestic and abroad, mainly in North America, Europe, Australia and mainland of China and other regions etc. MORE>>

We are a professional CNC machining manufacturer, with a senior engineering R&D Design Department and precision CNC Machining Center.

Services: CNC machining, precision lathe parts processing, mass production, rapid prototyping, sample parts, custom design non-standard hardware/plastic parts.

Processing: CNC machining, lathe processing, drilling, chamfering, tapping, milling flat knurling, cold heading, stamping, die-casting, wire cutting, etc.

Material: aluminum alloy, stainless steel, copper, iron, etc.

Surface treatment: grinding, polishing, electroplating, silk screen printing, passivation, blackening, radiation, heat treatment, drop-resistant glue, surface etching, anodizing, etc.

Processing equipments: CNC lathe, turning and milling compound CNC, 5-axis CNC machining center, Drill Grinder, etc.

Positioning accuracy: ±0.002mm

Repetitive positioning accuracy: ±0.003mm

Roundness boring \ Milling accuracy: ±0.002mm

Data form: 3D, 2D

File format: Sldprt, prt, CATPart, x_t, step, iges, dxf, dwg, pdf

20 years focus on CNC precision aluminum alloy parts processing, producing non-standard parts by your drawings or samples, advanced CNC machining center, witch can meet the diversified product demand of the market.

New energy auto accessories include: engine aluminum alloy shell, 6061 aluminium alloy automobile wheel hub, 3003 aluminum battery shell, anti-collision beam, seat parts, etc.

Aluminum camera accessories include: aluminum alloy tripod, camera handle, moisture-proof box, stabilizer, aluminum slide rail, tripod, camera shell, etc.

We cooperate with well-known robot manufacturers to produce aluminum alloy robot arm, controller parts, servo motors, gear reducer accessories.

A perfect international standard quality inspection system has been established, and every factory product has to go through many strict inspection procedures before it can be shipped.

With strict quality control process, to ensure the pass rate of 100% , less than 1% for three consecutive years, and we have a good reputation in the industry.

Completed quality inspection equipments, from the initial inspection and random inspection in the production stage to the full inspection in the packaging stage, apply international advanced equipment, and minimize the development cost, cycle and risk for customers through scientific and rigorous technological requirements.

We have efficient production capacity, build intelligent warehousing and cross-border logistics cooperation supply chain, and realize your delivery expectation more quickly.

There are 106 4-axis CNC machining centers (drilling and tapping, V8, 1160, etc.), 28 5-axis machining centers, 2 CNC die machines, 2 engraving and milling machines, 2 turning and milling machines, 4 CNC lathes, 9 injection molding machines, 4 CNC walkers, bending machines, high-precision sawing machines, grinding machines, spark machines, drilling machines, etc.

7*24 hours uninterrupted work, shorten the production cycle, and provide guarantee for your products to be put on the market in time.

—— CNC Machining Technology Blogs ——

5-axis CNC machining is widely used in industries such as aerospace, automotive, medical devices, and complex mold-making, where precision and intricate detail are paramount.

In the summer of 2024, the world will turn its eyes towards Paris, France. This occasion marks not only another chapter in the history of the Olympic Games but also introduces an Olympic torch design that marries unique brilliance with exquisite craftsmanship, guiding us into a r

Turning and milling technologies have evolved significantly with advancements in CNC technology, enabling higher precision, automation, and complex operations.

Custom manufacturing of aluminum chassis enclosures can involve several different processes, each with its own benefits and suitable applications.

CNC machining is a widely accepted set of processes in part and product manufacturing due to its accuracy, precision, and tolerance. Therefore, making it easy for product designers and manufacturers to create products of different complexity.

Yixin Chuangyan newly added several precision engraving 5-axis CNC machine and testing equipment

CNC precision metal parts surface treatment types

In order to better understand customer needs and feedback, and establish good business relationships, Yi Xin's business team has been on the road visiting customers since September 2023.Through close contact and conversations with customers, we sincerely felt their affirmatio

In today's era of rapid technological advancement, precise and efficient production methods have become the core competitiveness of the manufacturing industry. Among them, CNC machine tool (CNC) assembly technology, with its advantages of high precision and high degree of aut

With the advancement of science and technology and the diversification of market demand, the sheet metal processing industry is in the midst of a profound change, showing broad prospects and unlimited development potential. From the core pillar of traditional manufacturing t