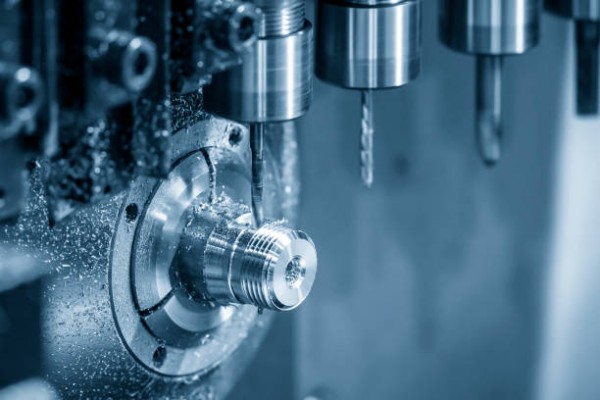

In the realm of advanced manufacturing, achieving unparalleled accuracy is no longer an option—it's a necessity. MM precision machining stands as a vital pillar of highaccuracy CNC manufacturing, enabling the production of complex components with micronlevel tolerances. Industries such as aerospace, automotive, electronics, and medical devices rely heavily on precision machining to ensure consistent quality, safety, and performance. Shenzhen Yixin Precision is committed to delivering exceptional CNC solutions that meet the evolving demands of these sectors.

Precision machining refers to the precise production of parts with dimensions measured in millimeters (mm) or micrometers (mm). Leveraging advanced CNC (Computer Numerical Control) systems, this process ensures highly consistent results, with deviations minimalized and products meeting stringent specifications.

Precision Machining increases performance by creating parts that fit seamlessly together, minimizing friction, wear, and mechanical failure - something of vital importance in industries where safety and reliability are of the utmost importance.

Achieving high precision cuts back on secondary operations and rework, thus decreasing production costs and improving efficiency.

At MM precision machining, every component meets our rigorous quality assurance protocols and international certifications such as ISO 9001.

Aerospace: Aircraft components must meet exacting tolerances in order to guarantee flight safety; even small deviations could lead to catastrophic failures and could compromise flight operations.

Automotive: Precision-machined parts such as engine blocks and transmission components help improve vehicle performance and longevity. Medical Devices: Implants and surgical instruments require accurate machining in order to ensure patient safety and functionality.

Electronics: For devices like smartphones and microchips to function efficiently, their small parts require precise measurements.

5axis and 7axis machines allow the creation of complex geometries more quickly with fewer setups, thus decreasing error margins and improving efficiency.

This technology delivers exceptional surface finish while cutting cycle times and mitigating thermal distortion.

Ideal for hard materials and intricate designs, EDM offers accurate tolerance control that cannot be achieved using conventional machining.

These devices measure and inspect machined parts to verify their accuracy according to specific tolerances through precise measurement.

Partner selection is crucial to the success of any project, so selecting an MM precision machining partner carefully should be top of your priority list. Key factors to keep in mind include:

Industry Experience: Working with an established provider will allow them to better understand and meet your specific needs. Modern Equipment: To deliver highprecision results, advanced CNC machinery and inspection tools must be available.

Quality Standards: Accreditations and compliance with international standards ensures reliability and consistency in output.

At Shenzhen Yixin Precision, we pride ourselves on offering top-of-the-line MM precision machining services tailored to our client's specific requirements. With cuttingedge technology and an experienced workforce supporting us as well as our commitment to quality assurance, Shenzhen Yixin Precision stands as an industry-leader partner.

Precision machining is more than a manufacturing process; it is the foundation of highaccuracy CNC production. As industries demand tighter tolerances and higher quality, its importance will only increase. By tapping advanced technologies and teaming with experienced providers like Shenzhen Yixin Precision, manufacturers can remain ahead of an increasingly competitive marketplace.