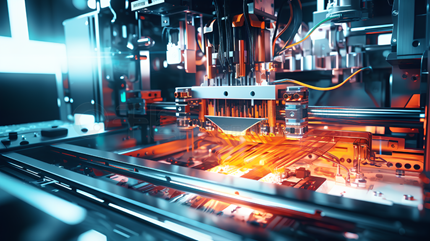

In today's era of rapidly changing science and technology, the importance of precision manufacturing technology has become increasingly prominent, and numerically controlled machine tool (CNC) processing, as the leader among them, is showing broad success on a global scale with its significant advantages such as high precision, high efficiency, and high degree of automation. development prospects.

1. Important role in the trend of intelligent manufacturing

With the further advancement of strategies such as "Industry 4.0" and "Made in China 2025", intelligent manufacturing has become the core driving force for the transformation and upgrading of the manufacturing industry. As an important part of intelligent manufacturing, CNC processing plays an indispensable role in this process due to its high degree of digitalization, networking and intelligence. Through deep integration with advanced technologies such as the Internet of Things, big data, and artificial intelligence, CNC processing equipment can realize advanced functions such as remote monitoring, fault prediction, and adaptive processing, further improving production efficiency, reducing operating costs, and promoting the manufacturing industry to become more intelligent and intelligent. Develop in a greener direction.

2. Market demand growth drives technological innovation

As the global economy continues to develop, various industries have an increasing demand for precision and complex components, especially in aerospace, automobile manufacturing, medical equipment, precision instruments and other fields, which have extremely high requirements for the accuracy, consistency, and complexity of components. Customized CNC machining service can meet the demanding requirements of these high-end manufacturing fields with its advantages of precise control and flexible programming. Facing the escalating market demand, CNC machining technology will continue to innovate. The research and development and application of cutting-edge technologies such as five-axis linkage, ultra-high-speed cutting, micro-nano machining, and composite material processing will further expand its application fields and enhance its market competitiveness.

3. Application of new materials creates new opportunities

The wide application of new materials such as high-temperature alloys, high-performance composite materials, and metal matrix composite materials in various fields has brought new challenges and opportunities to CNC processing. These new materials often have characteristics such as high strength, high hardness, and high temperature resistance, which are difficult to handle with traditional processing methods. However, CNC machining, with its customizable and refined processing strategies and its combination with advanced cutting tools, coolant and other supporting technologies, can effectively solve the processing problems of new materials while ensuring the processing quality, and pave the way for the large-scale production of new materials. It provides strong support for applications and also opens up new market space for CNC processing.

4. Green manufacturing concept leads sustainable development

Under the pressure of global environmental protection, the manufacturing industry is gradually shifting to a green, low-carbon, and circular development model. Due to its high precision and high efficiency, CNC machining can play an important role in reducing material waste and energy consumption. At the same time, with the promotion and application of green manufacturing technologies such as dry cutting, low-temperature cutting, and efficient cooling and lubrication in CNC processing, its environmental impact will be further reduced, resource utilization efficiency will be improved, and it will be in line with the sustainable development trend of the future manufacturing industry.

In summary, CNC machining technology has shown strong development momentum and broad development prospects, driven by the trend of intelligent manufacturing, market demand, the application of new materials, and the guidance of green manufacturing concepts. With the continuous innovation and improvement of technology, CNC processing will play a more critical role in the transformation and upgrading of the global manufacturing industry, contributing to the construction of an efficient, intelligent, and green modern manufacturing system.