Galvanizing, nickel plating, and chromium plating are three common electroplating surface treatment methods that are often used in CNC machining. But there are still certain considerations in which surface treatment method to choose. Let’s take a look with the editor to see what are the differences between these three types and their respective advantages and disadvantages, right?

1. Galvanizing

Material analysis: As a silver-white metal, zinc has good electrical and thermal conductivity, excellent anti-corrosion and anti-oxidation capabilities, and the output of zinc materials is generally larger and the cost is lower. Therefore, the production cost of zinc products is relatively controllable. It is one of the most commonly used materials in daily life and production.

Galvanizing is a process that uses electrolysis to attach a layer of zinc metal film to the surface of a material (which can be a metal material or other material), thereby preventing oxidation and corrosion of the target material. Because zinc itself has excellent electrical and thermal conductivity, corrosion resistance and wear resistance, galvanizing is a surface treatment method that is widely used. For example, the outer layer of screws, metal benches, balconies, ladders and fire escapes used in our daily lives is galvanized.

Since the zinc metal film acts as a sacrificial coating, it protects the underlying steel or iron from direct contact with water vapor, corrosive elements and other substances in the external environment, thus extending the service life of metal components.

2. Nickel plating

Material analysis: Nickel material itself has good ductility and plasticity, so it can be easily processed into nickel products of various shapes and sizes. At the same time, nickel materials have super corrosion resistance at room temperature, and can especially resist the erosion of many kinds of strong acids, strong alkali and salt water. This feature makes nickel materials widely used in aviation, chemical industry, navigation and nuclear industry. Not only that, compared to zinc, nickel also has good magnetic properties and can be made into permanent magnet materials.

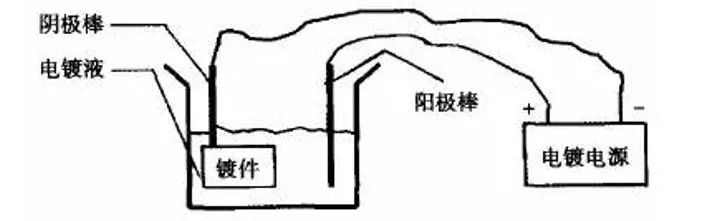

The method of plating a layer of nickel on metal or certain non-metals through electrolysis or chemical methods is called nickel plating. Nickel plating is divided into electroless nickel plating and chemical nickel plating.

1- Nickel electroplating is in an electrolyte composed of nickel salt/main salt, conductive salt, PH buffer, and wetting agent. Metal nickel is used for the anode, and plated parts are used for the cathode. Direct current is passed through. A uniform and dense nickel coating is deposited on the cathode (plated part).

2-Electroless nickel plating. Also called electroless nickel plating. Also called autocatalytic nickel plating. It refers to the process in which nickel ions in aqueous solution are reduced by reducing agents under certain conditions and precipitate to the surface of solid matrix.

Nickel plating surface treatment is commonly used in chemical industry, navigation, aerospace, automobile, machinery and electronic products.

3. Chrome plating

Material analysis: The chromium layer has strong adhesion, very high hardness, wear resistance and corrosion resistance, and also has high heat resistance. It does not have any discoloration reaction at 480°C and only begins to oxidize above 500°C. When the temperature rises At 700°C, the hardness will drop significantly.

Although the advantages of chromium are very obvious, its shortcomings are also very prominent, such as being hard, brittle, easy to fall off, and especially obvious when subjected to impact. On the other hand, the anti-corrosion effect of chromium plating on the surface of steel parts is not ideal. It usually requires multi-layer electroplating such as copper → nickel → chromium to achieve a better anti-rust effect.

Chrome plating: divided into two types. The first is for decoration, with a bright appearance and good wear resistance. The rust prevention ability is not as good as galvanizing, but it is worse than the oxidation process; the second is to increase the hardness and wear resistance of metal parts, which is the function of the parts. sex.

Application: Bright decorative parts on home appliances and electronic products, such as tools, faucets, etc.

The above describes the characteristics, advantages and disadvantages of the three types of electroplating. So what is the biggest difference between these three types of electroplating? Which electroplating method should be preferred in what situations?

The chromium plating process is mainly used to improve the surface hardness of target materials (non-steel materials), and has the advantages of beautiful appearance and anti-corrosion. At the same time, chromium plating has good chemical stability. It has no effect on most strong acids and alkalis.

Nickel plating is mainly wear-resistant, anti-corrosion, and anti-rust. It is generally thin in thickness. The process is divided into two categories: electroplating and chemical.

Galvanizing is mainly beautiful and rust-proof. Zinc is an active metal that can react with acids and has poor corrosion resistance. It is the cheapest of the three.

The difference in cost: chrome plating is the most expensive, followed by nickel and zinc is the cheapest. It is also necessary to distinguish between rack plating, barrel plating, etc. Rack plating is expensive, barrel plating is cheap.

Therefore, when choosing a specific electroplating process, you can make a comprehensive selection based on the user's budget and whether the workpiece needs to have a higher level of corrosion resistance and high temperature resistance.

Yixin Precision Metal & Plastic Ltd has been a one-stop service manufacturer focusing on aluminum alloy parts machining, automobile modification parts machining, photographic equipment and audio equipment precision parts processing, anodizing and assembly for many years, integrating production, processing and sales. As one, the company is located in Shajing Street, close to Bao'an International Airport, with convenient transportation. The engineering team spent a lot of time studying the effects of different aluminum alloy materials and different oxidation pigments on the anode, which has its unique advantages in the processing of precision aluminum alloy parts with high appearance requirements. Everyone is welcome to conduct on-site factory inspections.