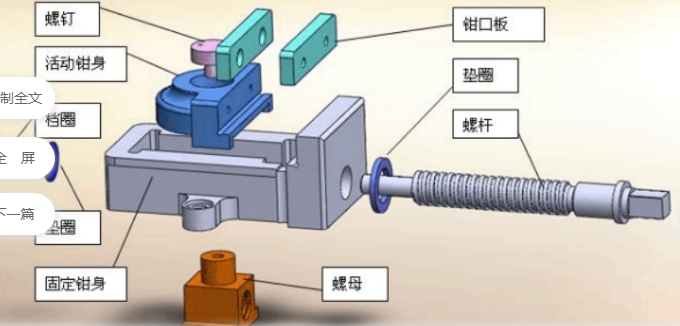

Vise, a fixture for holding workpieces, is generally made of mild steel, stainless steel, and other alloy steels. It is mainly used to complete various types of processing and assembly work. The vise has large clamping force and stability, and can complete various processing tasks requiring precision in the production process. It is widely used in CNC precision machining.

2. Types of vise:

1-Machine vise: used on machine tools to tighten and position workpieces.

2-Manual pliers: Commonly known as "vises", they are a daily tool that many people have in their homes.

3-Unit clamp: usually consists of a set of clamps that can be assembled as needed.

3. The function of vise

1-Clamp the workpiece. The vise can clamp and fix the workpiece on the CNC milling machine table to ensure that the bow and arrow will not move or shake during the processing, which will ensure the processing accuracy and quality to a large extent.

2-Adjust the position of the workpiece. The vise can accurately control the position and angle of the workpiece on the CNC milling machine by adjusting the clamping force and tightening position, thereby achieving more precise processing;

3-Adapt to workpieces of different shapes. The vise can be adjusted according to the shape and size of the workpiece to accommodate the processing of workpieces of different shapes and sizes.

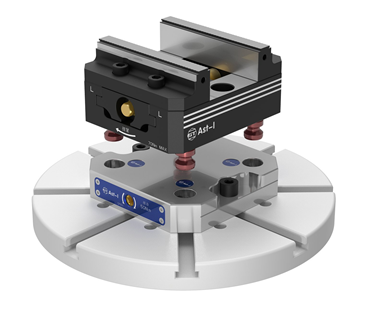

4. The installation method of the vise clamp is very simple.

a-Transport the vise to the designated machine table, calibrate it to the designated position, and then place the positioning block installed under the vise clamp in the T-shaped slot of the machining center workbench. The advantage of doing this is when performing heavy cutting processing. When doing this, prevent the vise clamp from deviating from the previously calibrated position, and also confirm the parallelism and perpendicularity of the clamp. The clamp is now installed.

B-Notes on workpiece installation:

1- Before installing the workpiece, confirm the parallelism and perpendicularity of the workpiece. If the parallelism and perpendicularity of the workpiece cannot be maintained well, the clamping force after the workpiece is installed will be greatly affected.

2-Be sure to ensure that the workpiece is installed in the middle of the fixture, and the clamping force of the fixture is consistent with the center of the workpiece, so that there will be no offset during the actual precision CNC machiningprocess.

3-Be careful not to use too much force when installing the workpiece clamp, otherwise excessive force will cause the bow and arrow to deform, and the processing accuracy will be adversely affected.

5. When using a vise, you should pay attention to the following matters:

1. Check the working surface of the fixture to ensure that it is not damaged or deformed to ensure the stability of the workpiece.

2. The size and weight of the workpiece need to be suitable for the vise, otherwise both the vise and the workpiece will be damaged.

3. The intensifier needs to be installed correctly on the machine tool or other workbench and tightened correctly.

4. When clamping the workpiece, attention needs to be paid to the increased clamping force to avoid excessive clamping, which may lead to deformation, damage, and poor processing.

5. When using a vise, you need to keep the machine area clean and safe to avoid safety accidents caused by random placement of debris or improper operation.

The vise is a very common fixture that is widely used in various production, processing and assembly processes. Yixin Precision Metal & Plastic Ltd is a one-stop service manufacturer integrating customized production, processing and assembly. It has multiple high-precision CNC engraving five-axis machining machines and has long-term services in aluminum alloy parts processing, photography and video equipment, audio equipment precision parts, medical equipment and other industries. Everyone is welcome to conduct on-site factory inspections.