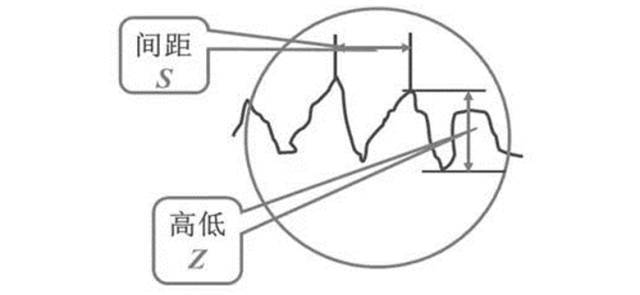

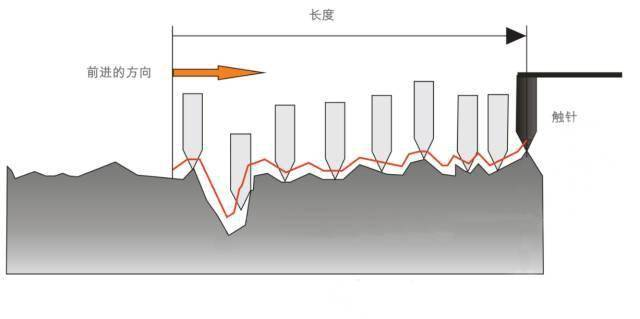

The surface of the processed part usually has a microscopic geometric shape composed of small spacing and tiny peaks and valleys. This geometric shape feature is called surface roughness, also called microscopic unevenness. The wave distance between the two wave crests or the two wave troughs is very small (usually less than 1 mm), which is a micro-geometric error.

The picture above shows the situation between the height (Z) and the spacing (S) of tiny peaks and valleys. Classified by spacing (S), it can generally be divided into three categories; namely, surface roughness, waviness, and f-shape.

1-S<1mm is surface roughness (microscopic unevenness);

2-1≤S≤10mm is waviness; waviness is a concept that describes the unevenness of the surface of an object. It can evaluate the flatness and accuracy of the surface of the object, as well as factors such as processing technology and materials that affect the surface quality of the object;

3-S>10mm is f shape.

It can be seen that the larger the surface roughness value, the rougher the surface.

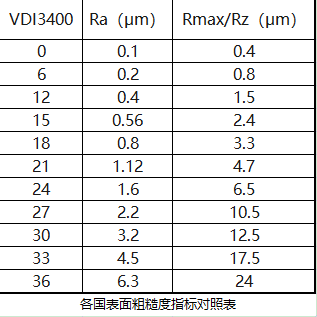

What are the names of surface roughness in various countries and their comparison:

1-Ra indicator is usually used in actual domestic production;

2-Rmax indicator, commonly used in Japan, has the same meaning as the Rz indicator;

3-VDI3400 indicator is a commonly used expression in European and American countries;

The picture above is a comparison table of the VDI3400 index in European and American countries, the domestic Ra index and the Japanese Rz index. Friends in need can download and save it directly.

The influence of surface roughness on parts is concentrated as follows:

· Will directly affect the wear resistance of parts; the rougher the surface, the smaller the effective contact area between surfaces. At the same time, due to the negative correlation between area and pressure, the smaller the contact area under a certain environment, the pressure will be The larger it is, the greater the friction resistance will be. It is conceivable that parts with rougher surfaces will wear faster and more frequently;

·The stability of the fit of parts in actual use; for clearance fit, the rougher the parts, the gap will gradually increase during the working process; for interference fit (depending on the interference value of the shaft and the hole, the parts will be (generate elastic pressure between surfaces to obtain a tight connection), squeezing the microscopic convex peaks flat during assembly reduces the actual effective interference, which will reduce the connection strength; and will lead to the stability of the fit of the parts in actual use. Reduced, thus affecting the final service life of the product;

·Fatigue strength (the maximum stress that a material can exert without causing damage under infinitely many alternating loads, is called fatigue strength or fatigue limit); there will be relatively large troughs on the surface of rough parts, which are very sensitive to stress concentration and will Reduce the fatigue strength of parts.

·Corrosion resistance and sealing: Rough parts will have more gaps on the surface, and these gaps will easily allow corrosive gases and liquids to penetrate deep into the metal through the microscopic valleys on the rough surface, exacerbating corrosion on the surface of the parts. This affects the corrosion resistance and sealing properties of the parts.

·Contact stiffness; contact stiffness enables the joint surface of parts to resist contact degeneration under the action of external forces. Rough part surfaces tend to reduce the contact stiffness of the parts;

·Measurement accuracy; in terms of surface roughness, it will directly affect the CNC machining parts. The most obvious effect is the measurement accuracy of the part surface.

Surface roughness is an important part of the quality inspection of CNC machining parts and is valued by major CNC custom machining service manufacturer. After all, surface roughness will directly and indirectly affect the final indicators of the part, which deserves everyone's attention.