With the rapid development of the intelligent manufacturing industry, the high-efficiency, stable, and high-precision machining of major complex parts in automobile manufacturing will effectively shorten the product production cycle and improve enterprise efficiency and competitiveness. CNC machining technology will enable rapid prototyping and manufacturing of complex automotive parts. At the same time, virtual manufacturing technology, flexible production technology and numerical control technology will be widely used in modern automobile manufacturing.

Compared with traditional processing methods, modern cnc processing technology accelerates the realization of standardized auto parts manufacturing, which provides a solid foundation for the improvement of domestic auto parts production quality and operating efficiency.

CNC technology can provide a complete set of automation solutions for the manufacture of major automotive parts. In the process of processing, the processing data of big data monitoring and remote service based on the industrial Internet can be accepted.

CNC machining has the following characteristics in automobile modification parts:

1-Extremely fast production speed.

CNC machining can provide shorter and faster production times. This is because CNC machining is highly automated, eliminating the need for tedious, labor-intensive manual machining. Certain steps help to speed up and optimize the running time of machines in the production planning process;

2- High degree of automation. With its highly automated advantages, CNC machining can not only greatly shorten the production and processing time, but also make the automobile manufacturing process more streamlined. For example: If you send a part to a CNC machine for fabrication, a robotic arm can assist in removing the part after completion.

3- Highly repeatable. As a computer-controlled machining process, automotive CNC machining also brings repeatability assurance. This is a critical key element in any industrial-grade production environment. In the automotive manufacturing industry, the consistency of parts batches is very important. All CNC lathes will need to meet exactly the same standards and parameters.

4- High precision. CNC machining is capable of achieving tight tolerances for target parts while meeting repeatability requirements. Especially for the automotive sector, this reliable machining result meets the tolerances required for engines and other functional components. Therefore, you can get extremely precise auto parts through CNC precision machining.

5- Support customer customization. CNC machining can help automobile manufacturers customize production and processing parts. According to the actual needs of customers, we can formulate complete solutions to meet customer requirements. CNC custom processing enterprises can also meet the customer's delivery time at the same time. We accept customized processing and production needs of 1-10000+ pieces.

Therefore, CNC machining can supply the following parts for the auto modification industry:

1- Complex components (blades, pistons, connecting rods);

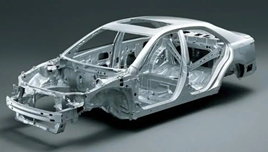

2- Body design: body frame, body parts, such as door handles, lamps, lathes, etc.;

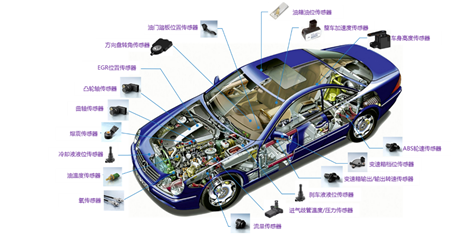

3-Automotive electronic parts processing: industrial sensors, actuators, controllers and other parts;

4- Automobile welding: welding structure, welding joints;